I will provide a service

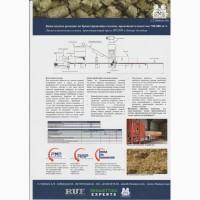

Solution for briquetting of straw, productivity 700-800kg/h, Lviv region.

Region:all of Ukraine,

Lviv region.

OOO "RMP BIOENERGIA" presents a complex solution for straw briquetting, consisting of the following plots:

- Crushing and grinding site

- A briquetting site with a hopper - dispenser

Straw briquettes can be used for different purposes, including the following:

- Thermal power engineering - industrial briquettes used in boilers for heat production

and energy

- Private sector -fuel briquettes for consumption in private households

- Gasification - high-density briquettes can be used on gasification installations

- Litter for animals - during briquetting, an impact-mechanical press breaks the structure of the molecular lattice, and the straw acquires unique hygroscopic properties. . The absorbency of straw increases 5-7 times. Thus, crushed briquettes can be used as bedding material for cattle, horses and cellular animals(//tractor-service.com)

- Biogas – the use of briquettes from straw in biogas plants can increase its production

- Fodder - briquettes can be used for animal feed - mixing of various additives is possible.

The briquetting press VR 5000 is equipped with a main engine with a power of 45 kW, the weight of the press is 5,000 kg, and the dimensions are 2,850 x 1,350 x 1,350 mm (LxWxH).

Straw crushing and grinding line

- Conveyor for straw - bales are placed on the conveyor and fed into the crusher;

- Crusher - the crusher opens bales and grinds straw to particles of ~ 100 mm;

- Stone catcher -shredded straw screening out stones. Stones of any size would damage the hammer crushercrusher and the briquetting press;

- Hammer crusher – hammer crusher reduces the size of crushed straw to particles of the required size, as a rule, it is 5-15 mm;

Cyclone filter - straw passes through a cyclone filter, where dust is separated from air. The straw enters the screw conveyor, and the dust, in turn, is returned to the technological process;

- Sand removal - sand is removed through a sieve located in the lower part of the screw conveyor leading to the hopper - dispenser.

- Crushing and grinding site

- A briquetting site with a hopper - dispenser

Straw briquettes can be used for different purposes, including the following:

- Thermal power engineering - industrial briquettes used in boilers for heat production

and energy

- Private sector -fuel briquettes for consumption in private households

- Gasification - high-density briquettes can be used on gasification installations

- Litter for animals - during briquetting, an impact-mechanical press breaks the structure of the molecular lattice, and the straw acquires unique hygroscopic properties. . The absorbency of straw increases 5-7 times. Thus, crushed briquettes can be used as bedding material for cattle, horses and cellular animals(//tractor-service.com)

- Biogas – the use of briquettes from straw in biogas plants can increase its production

- Fodder - briquettes can be used for animal feed - mixing of various additives is possible.

The briquetting press VR 5000 is equipped with a main engine with a power of 45 kW, the weight of the press is 5,000 kg, and the dimensions are 2,850 x 1,350 x 1,350 mm (LxWxH).

Straw crushing and grinding line

- Conveyor for straw - bales are placed on the conveyor and fed into the crusher;

- Crusher - the crusher opens bales and grinds straw to particles of ~ 100 mm;

- Stone catcher -shredded straw screening out stones. Stones of any size would damage the hammer crushercrusher and the briquetting press;

- Hammer crusher – hammer crusher reduces the size of crushed straw to particles of the required size, as a rule, it is 5-15 mm;

Cyclone filter - straw passes through a cyclone filter, where dust is separated from air. The straw enters the screw conveyor, and the dust, in turn, is returned to the technological process;

- Sand removal - sand is removed through a sieve located in the lower part of the screw conveyor leading to the hopper - dispenser.

Ad ID: #949457

(added by a registered user)

Permanent Ad Address:

Impressions / views for today: ?, total: ?

Similar recent ads

Among them there are many interesting ones...