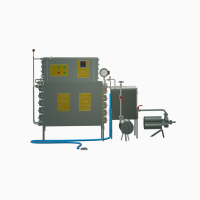

/ Сельхозтехника, оборудование, инвентарь / Brush Peshivnia (equipment) / Молокоперерабатывающее оборудование / = grease. / Pasteurizer of milk 300 liters

Продам / купить

Пастеризатор молока 300 літрів, Ровенская обл.

price= 210 000 грн.

Регион: вся Украина,

Ровенская обл.

(М. Рівне, вул. Володимира Стельмаха 18А)

== Updated:

= Pasteurizer of 300 liters-designed for heat treatment of milk, cream and other foods, works in the temperature range from 15 ° C to 90 ° C. In the heat treatment in the pasteurizer is destroyed, pathogenic microflora is neutralized. This increases the shelf life of dairy products without changing useful, taste, nutritional properties. There is heating without boiling, it eliminates the change in organoleptic parameters, the destruction of vitamins and enzymes.

= Pasteurizer of milk is intended: for pasteurization of milk, before the production of cheese, for pasteurization of milk under separator for the production of cream and butter=, for pasteurization of milk on the farm before Planting of the Montry || YES. All the materials of the pasteurizer of milk: exterior shell, inner capacity, lid, stirrer, crane of drain product - made of strong food stainless steel Aisi304. Milk pasteurizer will be useful for both calves on dairy farms and for milk processing enterprises пастеризованим свіжовидоєним молоком.

Всі матеріали пастеризатора молока: зовнішня обичайка, внутрішня ємність, кришка, мішалка, кран зливу продукту – виконані із міцної харчової нержавіючої сталі AISI304. Пастеризатор молока буде корисним як для випоювання телят на молочних фермах, так і для підприємств, що займаються переробкою молока.

= Milk pasteurizer allows the following operations:

heating, pasteurization of milk, cream and other foodstuffs;

fermentation of dairy products;

Milk turning;

Product mixing;

cooling.

The pasteurization process consists of sequential stages, which is manually controlled by or automatically and is displayed on the control unit:

= Loading product.

Set the pasteurization temperature. The heating of the product depends on the capacity of the installed TENs on the equipment (30 minutes in total). (// tractor-service.com)

After heating the product, the mode of maintaining a given temperature is turned on.

Operator disables heating and opens a tap with running water (optional: automatic mode).

= The product cooling process takes place.

During cooling on the display shows the temperature of the product at the moment.

Cooling with running water up to 15˚C (up to 2-4˚C with ice water (the required ice water generator is required, the pasteurizer must be made with panel shirt).

= The pasteurization process is completed.

At the request of the customer, the pasteurizer can be equipped with an automatic or semi -automatic control unit. It is also possible to make individual production of pasteurizers by customer size, the optimal choice of power of heating elements.

= Pasteurizer 300l allows the following pasteurization modes:

prolonged or low-temperature-heating up to 63-65 ° C with exposure for 25-30 min;

= short-term-heating up to 72-76 ° C with holding at this temperature for 20-60 s;

Instantial - 85 ° C and above without holding.

Also, our company additionally develops technological maps and carries out launching and installation work with staff training.

= For more information, contact our managers!

IKR GROUP.

= Pasteurizer of milk is intended: for pasteurization of milk, before the production of cheese, for pasteurization of milk under separator for the production of cream and butter=, for pasteurization of milk on the farm before Planting of the Montry || YES. All the materials of the pasteurizer of milk: exterior shell, inner capacity, lid, stirrer, crane of drain product - made of strong food stainless steel Aisi304. Milk pasteurizer will be useful for both calves on dairy farms and for milk processing enterprises пастеризованим свіжовидоєним молоком.

Всі матеріали пастеризатора молока: зовнішня обичайка, внутрішня ємність, кришка, мішалка, кран зливу продукту – виконані із міцної харчової нержавіючої сталі AISI304. Пастеризатор молока буде корисним як для випоювання телят на молочних фермах, так і для підприємств, що займаються переробкою молока.

= Milk pasteurizer allows the following operations:

heating, pasteurization of milk, cream and other foodstuffs;

fermentation of dairy products;

Milk turning;

Product mixing;

cooling.

The pasteurization process consists of sequential stages, which is manually controlled by or automatically and is displayed on the control unit:

= Loading product.

Set the pasteurization temperature. The heating of the product depends on the capacity of the installed TENs on the equipment (30 minutes in total). (// tractor-service.com)

After heating the product, the mode of maintaining a given temperature is turned on.

Operator disables heating and opens a tap with running water (optional: automatic mode).

= The product cooling process takes place.

During cooling on the display shows the temperature of the product at the moment.

Cooling with running water up to 15˚C (up to 2-4˚C with ice water (the required ice water generator is required, the pasteurizer must be made with panel shirt).

= The pasteurization process is completed.

At the request of the customer, the pasteurizer can be equipped with an automatic or semi -automatic control unit. It is also possible to make individual production of pasteurizers by customer size, the optimal choice of power of heating elements.

= Pasteurizer 300l allows the following pasteurization modes:

prolonged or low-temperature-heating up to 63-65 ° C with exposure for 25-30 min;

= short-term-heating up to 72-76 ° C with holding at this temperature for 20-60 s;

Instantial - 85 ° C and above without holding.

Also, our company additionally develops technological maps and carries out launching and installation work with staff training.

= For more information, contact our managers!

IKR GROUP.

|

store, contacts | |

= Vadym/= Lets, Info./оценка активности | |

|

Phone:

+380xxxxxx

показать

| |

Все объявления пользователя UAH 18a) | |

ID объявления: #1297819

(Added by the registered clerk, the date of registration: 25-07-2018)

= Added/Renewed: 22-04-2025 11: 38==. (Topically, to: 22-04-2026)

Постоянный адрес объявления:

Indications / Suspension for Today:?, All:?

= sets the announcements

= especially them. Automatic

All Ukraine:= Brush Pistons (Equipment)== 1462 / Молокоперерабатывающее оборудование = 181==/== greasy milk -replacing equipment + in Assortment = 77

= Rouvenskaya Region (оборудование)Пищевая промышленность (оборудование) 85 / Молокоперерабатывающее Equipment = 48 ||umber 440 =/ grease milk -replacing equipment + in Assortment = 28